Hydraulic shredder is a kind of equipment that uses hydraulic system to drive the tool to break and shred waste materials, which is widely used in the pretreatment of solid waste. Its main function is to tear large or difficult to handle materials (such as plastic, metal, wood, rubber, etc.) into smaller particles for subsequent recycling or treatment. The hydraulic shredder has the characteristics of high efficiency crushing, low energy consumption, low noise, low maintenance cost, and is equipped with overload protection and automatic reversal function to ensure the safe and reliable operation of the equipment.

| Availability: | |

|---|---|

| Quantity: | |

The Double Shaft Shredder is a versatile industrial machine designed for size reduction of diverse materials, including plastics, metals, rubber, and e-waste. With a dual-shaft design and hydraulic feeding system, it delivers high torque and low-speed operation, ensuring efficient shredding without excessive heat generation. Suitable for large-scale recycling plants and waste management facilities, this shredder handles 10-30 tons of material per hour .

Two counter-rotating shafts equipped with 42CrMo alloy steel blades generate powerful shear forces, tearing through bulky items like tires, furniture, and industrial drums. The adjustable blade spacing allows customization of output particle size (100-300 mm) .

The welded steel frame and thickened casing provide superior structural integrity, while the imported bearings with quadruple sealing protect against dust and moisture, ensuring long-term reliability.

Integrated PLC automation and touchscreen interface enable real-time monitoring of motor load, temperature, and torque. The overload protection feature automatically reverses the shafts to clear jams, minimizing downtime .

Plastic Recycling: Shreds PET bottles, PVC pipes, and plastic films into reusable flakes.

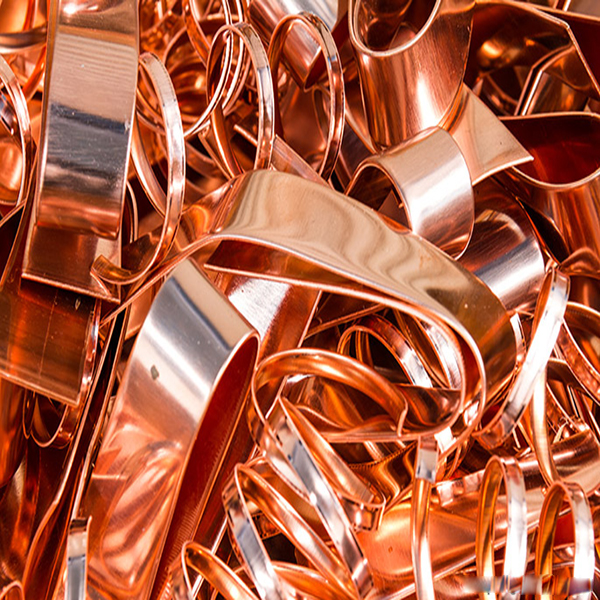

Metal Scrap Processing: Handles sheet metal, aluminum profiles, and cans, reducing them into transportable chunks.

Waste-to-Energy: Processes MSW (municipal solid waste) and biomass into fuel pellets for energy production.

E-Waste Disposal: Breaks down computers, TVs, and appliances, facilitating metal recovery .

Q: What materials are unsuitable for the Double Shaft Shredder?

A: It is not recommended for highly abrasive materials (e.g., concrete) or explosive waste.

Q: How does the hydraulic feeding system work?

A: The hydraulic ram pushes bulky materials into the shredding chamber, ensuring consistent feeding and maximizing throughput .

Q: Can the shredder be integrated into existing production lines?

A: Yes. It supports customizable inlets/outlets and PLC integration for seamless integration with conveyors, separators, and balers.

Parameter | Value |

Model | GDI Series |

Processing Capacity | 5-50 tons/hour |

Motor Power | 75-400 kW |

Blade Material | 42CrMo Alloy Steel |

Output Size | 100-300 mm |

Feeding System | Hydraulic Ram |

Control System | PLC with Touchscreen |

Weight | 5-20 tons |

Dimensions | 5,000×2,650×3,300 mm (GDI8) |

01

Hydraulic shredder adopts low speed, high torque hydraulic drive mode, equipped with high strength alloy tool, can efficiently deal with various hardness and shape of materials. The equipment is usually composed of feeding system, shredding system, hydraulic system, screen system and electrical control system.

02

The working principle of the hydraulic shredder is to send the material into the shredding box through the hydraulic pushing device, and the tool tears, extruded and cut the material at low speed, and finally breaks the material into small pieces.

03

The hydraulic shredder adopts a unique tool shaft structure and rotary tool, which can produce strong shredding force at low speed, while avoiding entanglement or stuck phenomenon.

04

Convenient maintenance. The hydraulic shredder is simple in structure, and the cutting tool is made of high strength alloy steel material, which is wear-resistant and repairable, reducing the maintenance cost.

Model | ALVA-DSSM-600 | ALVA-DSSM-800 | ALVA-DSSM-1000 | ALVA-DSSM-1200 | ALVA-DSSM-1400 | ALVA-DSSM-1600 | ALVA-DSSM-1800 |

Blade thickness (mm) | 30 | 40 | 40 | 50 | 70 | 80 | 100 |

Number of tools | 40 | 40 | 50 | 48 | 40 | 40 | 36 |

Motor power (kw) | 15kw*2 | 22kw*2 | 37kw*2 | 55kw*2 | 75kw*2 | 90kw*2 | 110kw*2 |

Speed (r/min) | 15~18 | 15~18 | 12~15 | 12~15 | 9~12 | 8~10 | 5~8 |

Broken mouth size (mm) | 600*480 | 800*650 | 1000*680 | 1200*780 | 1400*880 | 1600*980 | 1800*1180 |

Scrap Metal

Scrap Iron

Scrap Copper

aluminum-scrap

Can-disposal

Waste bicycle

Waste paint bucket

Waste motorcycle

Waste Car

Waste plastics

Waste appliances

Customizable

|  |  |  |  |  |

|  |  |  |  |  |