Views: 0 Author: Site Editor Publish Time: 2026-01-20 Origin: Site

In today's world, plastic waste has become one of the most significant environmental challenges. As industries and individuals alike strive to reduce plastic waste, plastic crushers play an essential role in breaking down large quantities of plastic into smaller, manageable pieces. Whether used in recycling centers, manufacturing plants, or at home, these machines help reduce plastic waste, enabling its reuse and recycling into new products. However, choosing a reliable plastic crusher manufacturer is critical for ensuring high-quality equipment that will stand the test of time and deliver the best value for your investment.

In this article, we will explore the key factors to consider when selecting a plastic crusher manufacturer. We will delve into the different types of plastic crusher machines, what to look for in a plastic crusher manufacturer, and how to make an informed decision. Whether you’re looking for a plastic bottle crusher for home use, or a large-scale industrial crusher, understanding these critical factors will help guide your purchase.

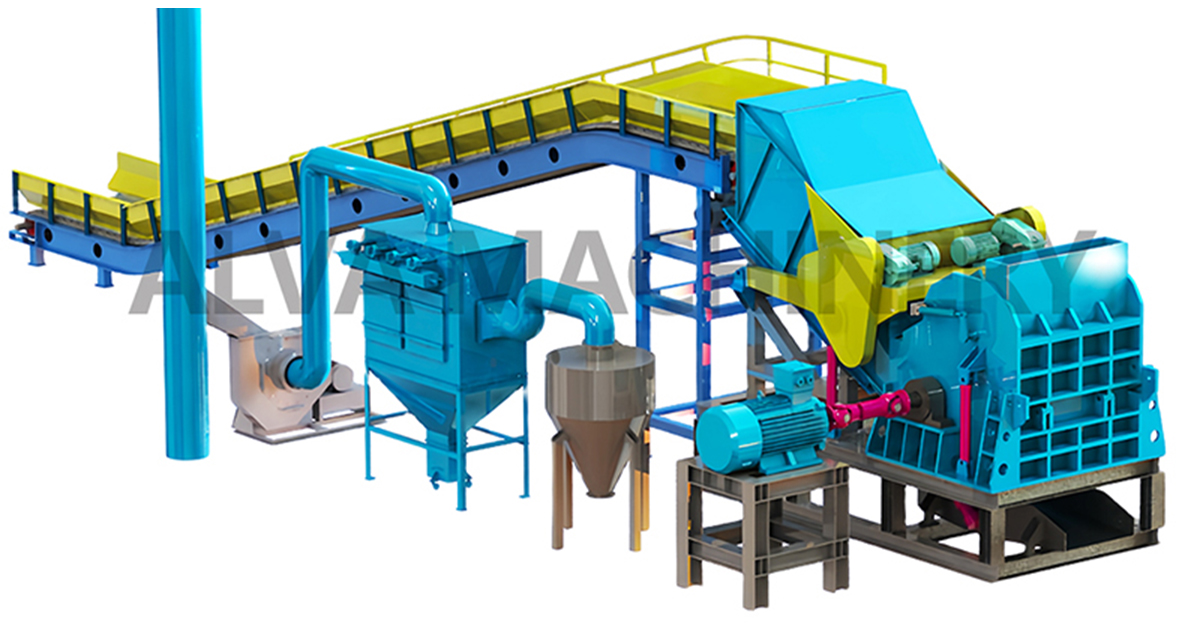

A plastic crusher is a machine designed to break down plastic materials into smaller, more manageable pieces for recycling. These machines are used in various industries to process plastic waste, such as bottles, films, pipes, and containers, and convert them into granules that can be reused in production processes.

The plastic crusher machine works by using sharp blades or rotary cutters that rotate at high speeds to shred plastic materials. The processed plastic is typically collected in a container or hopper, ready to be used again or further processed.

Plastic crushers are crucial for managing plastic waste efficiently. They are used in various applications, including plastic recycling facilities, waste management plants, manufacturing industries, and even homes for smaller-scale recycling purposes.

When selecting a plastic crusher, it’s important to understand the different types of machines available. Plastic crushers can vary in design, size, capacity, and application. Below are some of the most common types of plastic crushers:

Plastic Bottle Crushers

Used primarily for breaking down plastic bottles, these crushers are widely used in both industrial and home settings. Plastic bottle crushers for home use are generally smaller and more compact, designed to crush PET bottles into manageable pieces. Larger models are used in industrial recycling plants to process large volumes of plastic waste.

Manual Plastic Crushers

These crushers are typically used for small-scale operations or in homes where plastic waste generation is minimal. They operate manually, requiring physical effort to crush plastic materials. Despite their simplicity, manual crushers can be effective for reducing plastic waste in smaller quantities.

Automatic Plastic Crushers

Automatic plastic crushers are designed for large-scale, industrial use. They are equipped with advanced systems for automatic feeding, shredding, and collecting plastic materials. These machines are ideal for high-volume operations and require minimal manual labor.

Heavy-Duty Plastic Crushers

These are used in industries that deal with tough plastic materials, such as thick plastic pipes or large plastic profiles. These crushers are built to withstand heavy-duty usage and are typically used in large-scale recycling operations.

Selecting a reliable plastic crusher manufacturer is crucial for ensuring that you get a high-quality machine that meets your specific needs. Below are some key factors to consider when making your selection:

A manufacturer’s reputation is a critical indicator of the quality of their products. Look for plastic crusher manufacturers with a proven track record of producing high-quality machines. Established companies with years of experience are likely to have the technical expertise and resources needed to deliver durable, efficient crushers.

Research the manufacturer's history: Check how long the company has been in business and what kinds of machines they have produced in the past.

Customer reviews and testimonials: Look for customer feedback on the manufacturer’s website or third-party review sites. Positive reviews and testimonials from customers in similar industries can give you confidence in their products.

The quality and durability of the plastic crusher machine are essential factors to consider. A well-built machine will operate reliably over time and withstand the demands of daily use. High-quality crushers tend to have stronger frames, better motors, and sharp blades that ensure efficient plastic shredding.

Materials used in construction: Look for manufacturers that use durable materials like hardened steel or alloy for the blades and frame.

Longevity of the machine: Reliable manufacturers often offer warranties or guarantees that ensure their machines will last. Machines made from high-quality materials and components will perform efficiently for years.

Different operations require different types of plastic crushers. A reliable manufacturer should offer machines that are versatile and capable of handling various types of plastic materials. Look for manufacturers that provide customization options, allowing you to choose features that best suit your needs.

Adjustable settings: The best crushers allow you to adjust the blade speed, cutting chamber size, and output granule size for flexibility in handling different plastic materials.

Automatic features: Consider whether an automatic or semi-automatic crusher is more suitable for your needs. Some manufacturers offer plastic crusher machines with automated feeding systems and safety features.

After-sales support is an essential factor when selecting a plastic crusher manufacturer. A reliable manufacturer should offer excellent customer service, including maintenance, repairs, and technical support, to ensure your machine continues to operate smoothly.

Warranty and repair services: Ensure that the manufacturer offers a comprehensive warranty on the plastic crusher machine and provides easy access to repair services if needed.

Availability of spare parts: Check if the manufacturer provides readily available spare parts and has a service network to support the machine’s ongoing maintenance needs.

While quality is important, cost-effectiveness should also be a factor in your decision-making process. The initial cost of purchasing a plastic crusher is a significant investment, but it’s important to balance cost with the value the machine provides. Consider both the upfront price and the long-term savings from reduced labor costs and increased recycling efficiency.

Total cost of ownership: Factor in the machine’s operating costs, such as energy consumption, maintenance costs, and the price of spare parts.

Long-term value: A reliable machine that lasts for years and operates efficiently will provide more value over time, even if the initial purchase price is higher.

Ensure that the plastic crusher manufacturer you choose complies with relevant industry standards and regulations. Machines that meet quality and safety standards will help you avoid costly legal issues and ensure that the equipment operates safely and efficiently.

ISO certifications: Look for manufacturers that have ISO certifications or other industry-specific certifications, which indicate that their machines meet internationally recognized quality standards.

Safety features: Reliable manufacturers prioritize safety, incorporating features such as overload protection, emergency stop buttons, and safety covers to prevent accidents.

Consider the location of the plastic crusher manufacturer and how that affects logistics. If you are sourcing a crusher from plastic crusher China or another international manufacturer, factor in shipping costs and import duties. Additionally, check how easy it will be to obtain spare parts and support if needed.

Proximity to your operation: If the manufacturer is located far away, shipping costs and delivery times may increase, impacting your operational efficiency.

Local service availability: Consider whether the manufacturer has a local service center or distributor in your area to ensure quick repairs and maintenance.

When selecting a plastic crusher manufacturer, you will likely be faced with the decision of whether to choose a local supplier or an international manufacturer, such as those based in plastic crusher China. Both options have their advantages and disadvantages.

Local manufacturers: Often offer faster delivery times, better after-sales service, and lower shipping costs. However, they may have fewer customization options or less advanced technology than international suppliers.

International manufacturers: Companies based in countries like China often offer lower prices, a wider range of models, and advanced technology. However, importing machinery from abroad can lead to longer delivery times and higher shipping costs, and you may face language barriers or difficulty accessing local support.

A plastic crusher machine is a device used to shred plastic materials into smaller, more manageable pieces for recycling or reuse. It is commonly used in recycling plants, manufacturing facilities, and even homes for small-scale plastic waste management.

When choosing a plastic crusher manufacturer, consider factors such as reputation, machine quality, customization options, after-sales service, cost-effectiveness, and compliance with industry standards.

Common types of plastic crushers include plastic bottle crushers, manual crushers, automatic crushers, and heavy-duty industrial crushers. The type you choose depends on your specific needs and the volume of plastic waste you need to process.

Both local and international manufacturers have their advantages. Local suppliers may offer faster delivery and better support, while international manufacturers may provide more advanced technology and lower prices. Consider the trade-offs based on your specific needs.

An automatic plastic crusher machine offers increased efficiency, reduced labor costs, improved safety, and greater consistency in processing plastic materials. These machines are ideal for large-scale operations that handle high volumes of plastic waste.

Selecting a reliable plastic crusher manufacturer is crucial to ensuring you receive a high-quality, durable machine that meets your operational needs. By considering factors such as machine quality, after-sales support, cost-effectiveness, and the manufacturer’s reputation, you can make an informed decision that will pay off in the long term. Whether you are in need of a plastic bottle crusher for home use or an industrial-grade plastic crusher machine, the right manufacturer will provide the tools and support necessary to streamline your plastic waste management and recycling efforts.