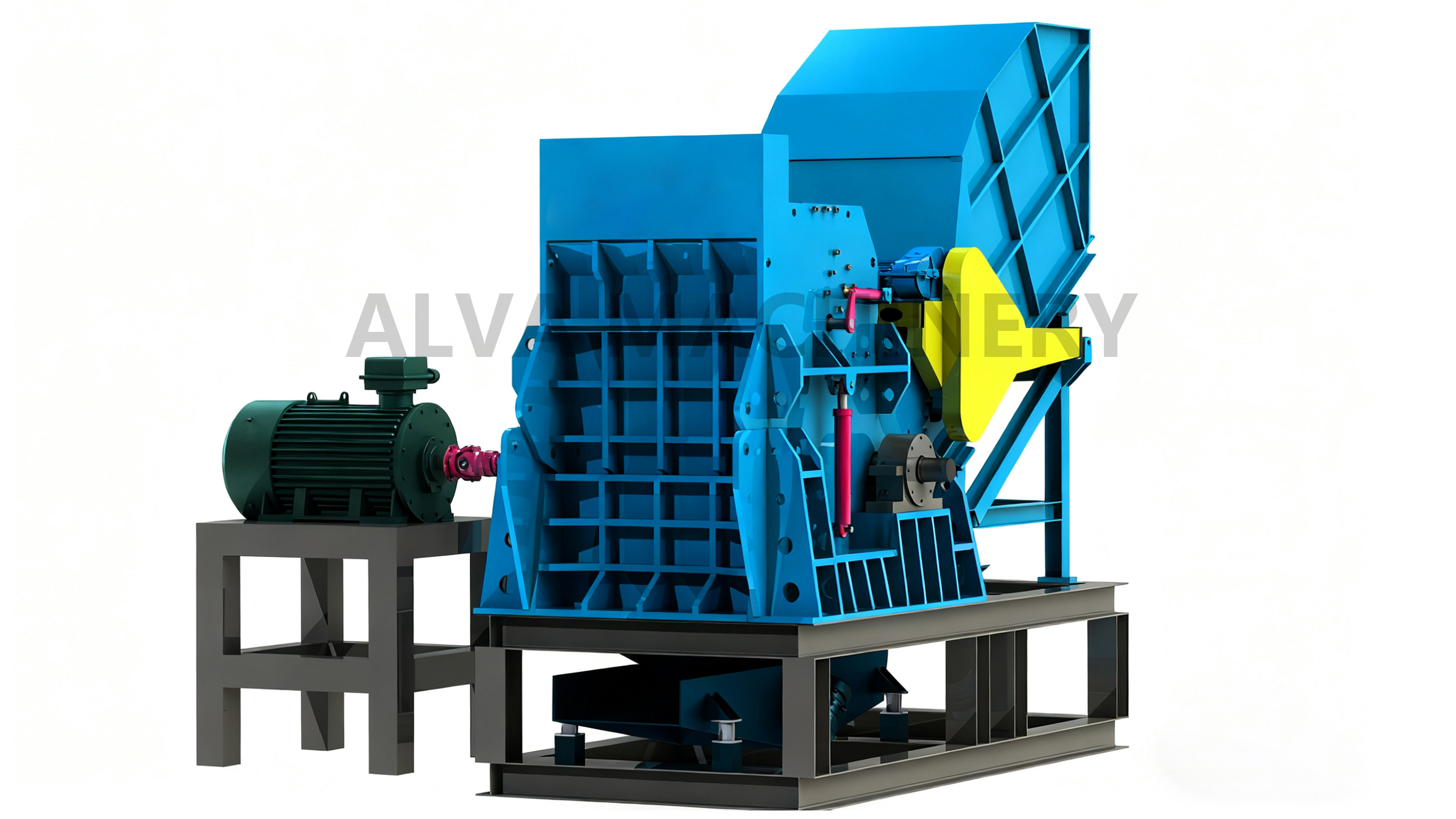

A classic example of Alva's small-scale metal shredder, the Model 80 Metal Shredder is designed for small and medium-sized recycling companies and individual businesses. It's suitable for shredding lightweight metal materials such as scrap cans, paint cans, and thin metal sheets. Equipped with a 7.5kW high-efficiency motor and a feed port measuring 200×250mm, it can achieve a crushing capacity of 0.5-1 ton per hour. The crushed material maintains a uniform particle size of 20-50mm, meeting the needs of subsequent packaging, recycling, or smelting pre-processing. The compact design of the entire machine, measuring only 1.2×0.8m, requires no complex foundation construction and can be operated and maintained by a single person. Equipped with wear-resistant manganese steel hammers and an automatic material removal device, it effectively reduces equipment wear and downtime, making it an ideal choice for launching a metal recycling business at a low cost.

| Availability: | |

|---|---|

| Quantity: | |

01

High-strength load-bearing chassis and outstanding structural stability:The chassis is constructed of high-strength alloy steel. The steel plates in key load-bearing areas are 16-20mm thick, increasing overall impact strength by over 40% compared to ordinary steel. This allows the machine to easily withstand the instantaneous loads caused by metal material impact during the crushing process, preventing chassis deformation.

02

Refined welding details: Arc transition welding is used at corners to avoid stress concentration; after welding, the welds are ground and polished to ensure a smooth appearance and reduce the risk of jamming during material transportation, ensuring that the welded parts can withstand high-intensity operations for a long time without the risk of loosening or breakage.

03

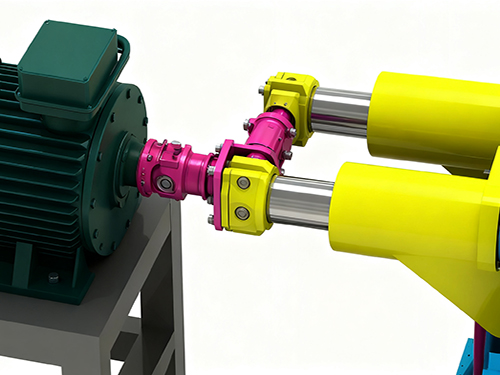

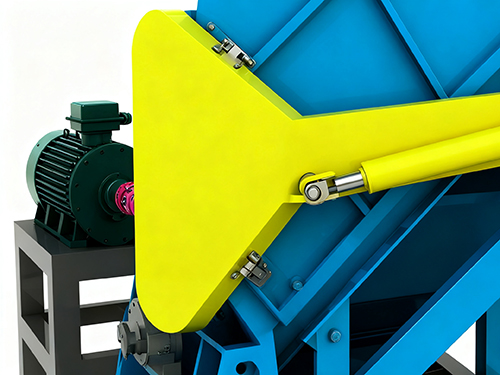

Highly adaptable motor power configuration: Equipped with a national standard series three-phase asynchronous motor, the power output is reduced by a hardened gear reducer, providing stable torque to the crushing cutter shaft, easily crushing medium- and high-strength metal materials such as cast iron and stainless steel.

04

High crushing efficiency: relying on the strong power of the motor and the optimized design of the crushing knife group, the feeding efficiency is greatly improved. The crushing particle size is controllable: equipped with a multi-stage adjustable screen. By replacing the screen, the particle size of the crushed material can be accurately controlled. The particle size deviation is ≤±2mm, which meets the material requirements of different scenarios such as recycling smelting and metal recycling.

| Model | Feed Size (mm) | Production Capacity | Energy Consumption | Energy Consumption | Load Bearing | External Dimensions | External Dimensions | External Dimensions | External Dimensions |

| Monolithic Output (th) | Fan Motor Power (kW) | Distribution Transformer Requirements (kVA) | Weight (kg) | Length (L, m) | Width (W, m) | Height (H, m) | Floor Area (㎡) | ||

| ALVA-MCM-75 | 900 | 1 | 75 | 125 | 5 | 4 | 3.7 | 3 | 12 |

| ALWA-MOM-110 | 1000 | 1.5 | 110 | 160 | 11 | 4 | 4 | 3.5 | 96 |

| ALWA-MOM-132 | 1260 | 2 | 132 | 200 | 16 | 4.5 | 4.8 | 3.5 | 140 |

| ALMW-MOM-160 | 1460 | 3-4 | 160 | 250 | 26 | 5 | 4.9 | 3.5 | 160 |

| ALVA-MCM-200 | 1500 | 4-5 | 200 | 315 | 35 | 6 | 4.9 | 3.5 | 250 |

| ALVA-MCM-315 | 1600 | 6-7 | 315 | 500 | 40 | 6 | 4.9 | 3.5 | 250 |

| ALVA-MCM-450 | 1600 | 8-9 | 450 | 630 | 55 | 7 | 4.9 | 4 | 300 |

| ALVA-MCM-630 | 1800 | 10-11 | 630 | 10,000 | 75 | 7.5 | 6 | 4 | 400 |

Scrap Metal

Scrap Iron

Scrap Copper

aluminum-scrap

Can-disposal

Waste bicycle

Waste paint bucket

Waste motorcycle

Waste Car

Waste plastics

Waste appliances

Customizable

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

We crush and recycle all kinds of raw aluminum, aluminum alloys, aluminum profiles, thermally-insulated aluminum, and waste cans.

Preparation: Check all parts of the equipment to ensure they are normal, clean the scrap aluminum to be crushed and transport it to the feed port.

Start the equipment: Turn on the crusher according to the instructions on the operation panel, and start feeding evenly after it runs smoothly without load.

Crushing operation: The scrap aluminum is crushed in the crushing chamber, and the equipment operation status is monitored during the process.

Discharge collection: The crushed aluminum material is discharged and collected and processed by screening.

Shutdown and cleaning: After the operation is completed, turn off the equipment and clean up the residual materials and equipment.