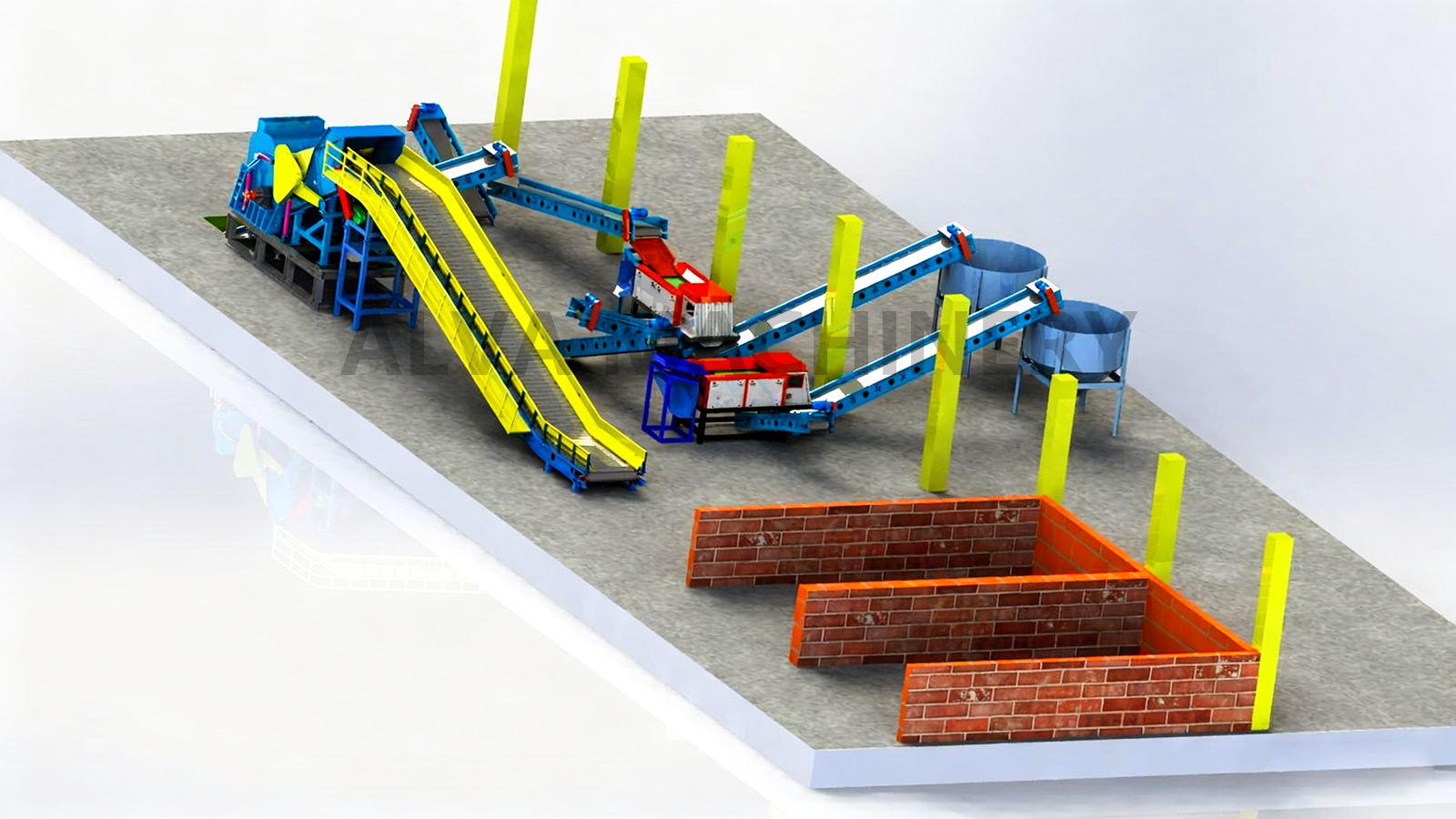

The Model 900 metal shredder, a benchmark for large-scale crushing equipment in Alva, is designed specifically for large-scale recycling parks and steel complexes. It meets the demands of annual processing capacity of tens of thousands of tons of metal scrap, including scrapped train carriages, large bridge steel structures, and thick-walled boilers. Equipped with a 250-315kW high-power motor and a feed opening measuring 1200×1500mm, it boasts a crushing capacity of 20-30 tons per hour. The crushing chamber is welded from high-strength manganese steel with a compressive strength of 1200MPa. The hydraulically adjustable discharge opening allows for flexible control of the finished product size between 50 and 150mm. The equipment is equipped with multiple safety features, including infrared human presence detection, hydraulic overload relief, and motor overheating protection. Its modular design standardizes the replacement of wearing parts and equipment maintenance, ensuring continuous production stability.

| Availability: | |

|---|---|

| Quantity: | |

01

The machine body is constructed from high-strength, welded alloy steel, ensuring a stable structure that can withstand the powerful impact and vibration during the crushing process, ensuring long-term stable operation. The surface is also treated with an anti-corrosion treatment for wear and rust resistance, extending its service life.

02

CNC System

Equipped with an advanced PLC CNC system, it precisely controls operating parameters such as crushing speed and feed rate, enabling automated operation. It also features fault diagnosis and early warning functions, facilitating timely maintenance and ensuring production efficiency and safety.

03

Conveyor Belt

Made from wear-resistant and non-slip materials, it delivers smooth transmission and high conveying efficiency, adapting to the continuous conveying needs of materials of varying sizes. Its rational design allows for easy adjustment of tension and deviation, minimizing jamming and loss during conveying.

04

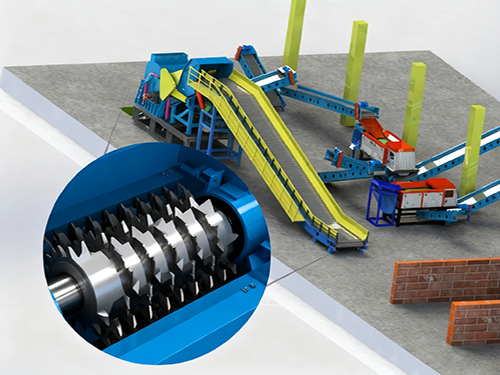

Blades

Made from carbide and undergoing a special heat treatment process, they offer high hardness, excellent toughness, and long-lasting sharpness, enabling efficient crushing of a wide range of materials. The blades are easy to install and replace, reducing maintenance costs and enhancing the continuity and reliability of crushing operations.

| Model | Feed Size (mm) | Production Capacity | Energy Consumption | Energy Consumption | Load Bearing | External Dimensions | External Dimensions | External Dimensions | External Dimensions |

| Monolithic Output (th) | Fan Motor Power (kW) | Distribution Transformer Requirements (kVA) | Weight (kg) | Length (L, m) | Width (W, m) | Height (H, m) | Floor Area (㎡) | ||

| ALVA-MCM-75 | 900 | 1 | 75 | 125 | 5 | 4 | 3.7 | 3 | 12 |

| ALWA-MOM-110 | 1000 | 1.5 | 110 | 160 | 11 | 4 | 4 | 3.5 | 96 |

| ALWA-MOM-132 | 1260 | 2 | 132 | 200 | 16 | 4.5 | 4.8 | 3.5 | 140 |

| ALMW-MOM-160 | 1460 | 3-4 | 160 | 250 | 26 | 5 | 4.9 | 3.5 | 160 |

| ALVA-MCM-200 | 1500 | 4-5 | 200 | 315 | 35 | 6 | 4.9 | 3.5 | 250 |

| ALVA-MCM-315 | 1600 | 6-7 | 315 | 500 | 40 | 6 | 4.9 | 3.5 | 250 |

| ALVA-MCM-450 | 1600 | 8-9 | 450 | 630 | 55 | 7 | 4.9 | 4 | 300 |

| ALVA-MCM-630 | 1800 | 10-11 | 630 | 10,000 | 75 | 7.5 | 6 | 4 | 400 |

Scrap Metal

Scrap Iron

Scrap Copper

aluminum-scrap

Can-disposal

Waste bicycle

Waste paint bucket

Waste motorcycle

Waste Car

Waste plastics

Waste appliances

Customizable

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |