The 630 metal shredder is designed for large-scale crushing applications and is suitable for the batch crushing needs of large-scale scrap steel processing bases and scrapped vehicle dismantling centers. It can efficiently process ultra-heavy metal materials such as entire vehicle frames, large steel structures, and thick-walled pressure vessels. Equipped with a 110-160kW dual-motor drive system and an inlet size of 800×900mm, it has a crushing capacity of 10-15 tons per hour. Its "tapered" crushing chamber design and 20 sets of high-wear-resistant alloy hammers can easily crush steel plates up to 20mm thick and steel pipes up to 300mm in diameter. Equipped with a hydraulic pusher and an intelligent monitoring system, the machine monitors chamber pressure and motor load in real time, automatically adjusting the feed rate. Combined with a heavy-duty crawler-type discharge conveyor, it achieves integrated crushing and conveying operations, significantly improving production efficiency.

| Availability: | |

|---|---|

| Quantity: | |

01

Performance

It offers excellent crushing performance, enabling efficient and uniform crushing of materials such as scrap steel and iron. It can quickly crush various scrap specifications to the desired particle size, achieving high crushing efficiency and a large processing capacity. Furthermore, the crushing process consumes minimal energy, ensuring effective crushing while helping to reduce production and operating costs and improve overall productivity.

02

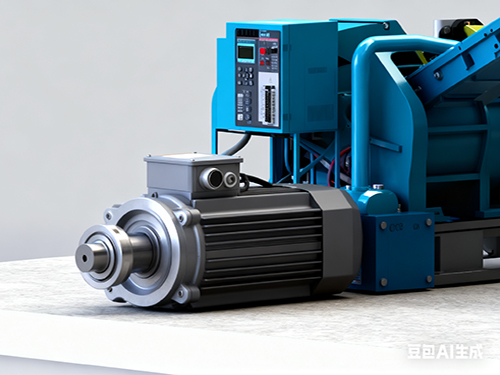

Motor

Equipped with a high-efficiency motor, it delivers powerful power and stable operation. Advanced motor technology provides ample torque, ensuring the crusher maintains efficient operation when processing materials such as scrap steel and iron. The motor also features excellent heat dissipation, allowing for long periods of continuous operation, reducing the risk of failure due to overheating and ensuring stable equipment operation.

03

Body

Constructed from high-strength steel, the body provides a sturdy and reliable structure. Precision welding and machining processes ensure robust overall rigidity, capable of withstanding the significant impact and vibration generated during the crushing process. This effectively prevents deformation, extends the equipment's service life, and provides a stable support for crushing operations.

04

Mechanism

Each mechanism is scientifically and rationally designed, working together smoothly. The feeding mechanism can stably and continuously transport scrap steel and iron materials to avoid feed blockage; the layout of the cutters or hammers in the crushing mechanism is optimized, with strong crushing capacity and good crushing effect on scrap steel and iron; the discharging mechanism can discharge the crushed materials in time, ensuring the continuity and efficiency of the entire crushing process and improving the overall operating performance of the equipment.

| Model | Feed Size (mm) | Production Capacity | Energy Consumption | Energy Consumption | Load Bearing | External Dimensions | External Dimensions | External Dimensions | External Dimensions |

| Monolithic Output (th) | Fan Motor Power (kW) | Distribution Transformer Requirements (kVA) | Weight (kg) | Length (L, m) | Width (W, m) | Height (H, m) | Floor Area (㎡) | ||

| ALVA-MCM-75 | 900 | 1 | 75 | 125 | 5 | 4 | 3.7 | 3 | 12 |

| ALWA-MOM-110 | 1000 | 1.5 | 110 | 160 | 11 | 4 | 4 | 3.5 | 96 |

| ALWA-MOM-132 | 1260 | 2 | 132 | 200 | 16 | 4.5 | 4.8 | 3.5 | 140 |

| ALMW-MOM-160 | 1460 | 3-4 | 160 | 250 | 26 | 5 | 4.9 | 3.5 | 160 |

| ALVA-MCM-200 | 1500 | 4-5 | 200 | 315 | 35 | 6 | 4.9 | 3.5 | 250 |

| ALVA-MCM-315 | 1600 | 6-7 | 315 | 500 | 40 | 6 | 4.9 | 3.5 | 250 |

| ALVA-MCM-450 | 1600 | 8-9 | 450 | 630 | 55 | 7 | 4.9 | 4 | 300 |

| ALVA-MCM-630 | 1800 | 10-11 | 630 | 10,000 | 75 | 7.5 | 6 | 4 | 400 |

Scrap Metal

Scrap Iron

Scrap Copper

aluminum-scrap

Can-disposal

Waste bicycle

Waste paint bucket

Waste motorcycle

Waste Car

Waste plastics

Waste appliances

Customizable

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |