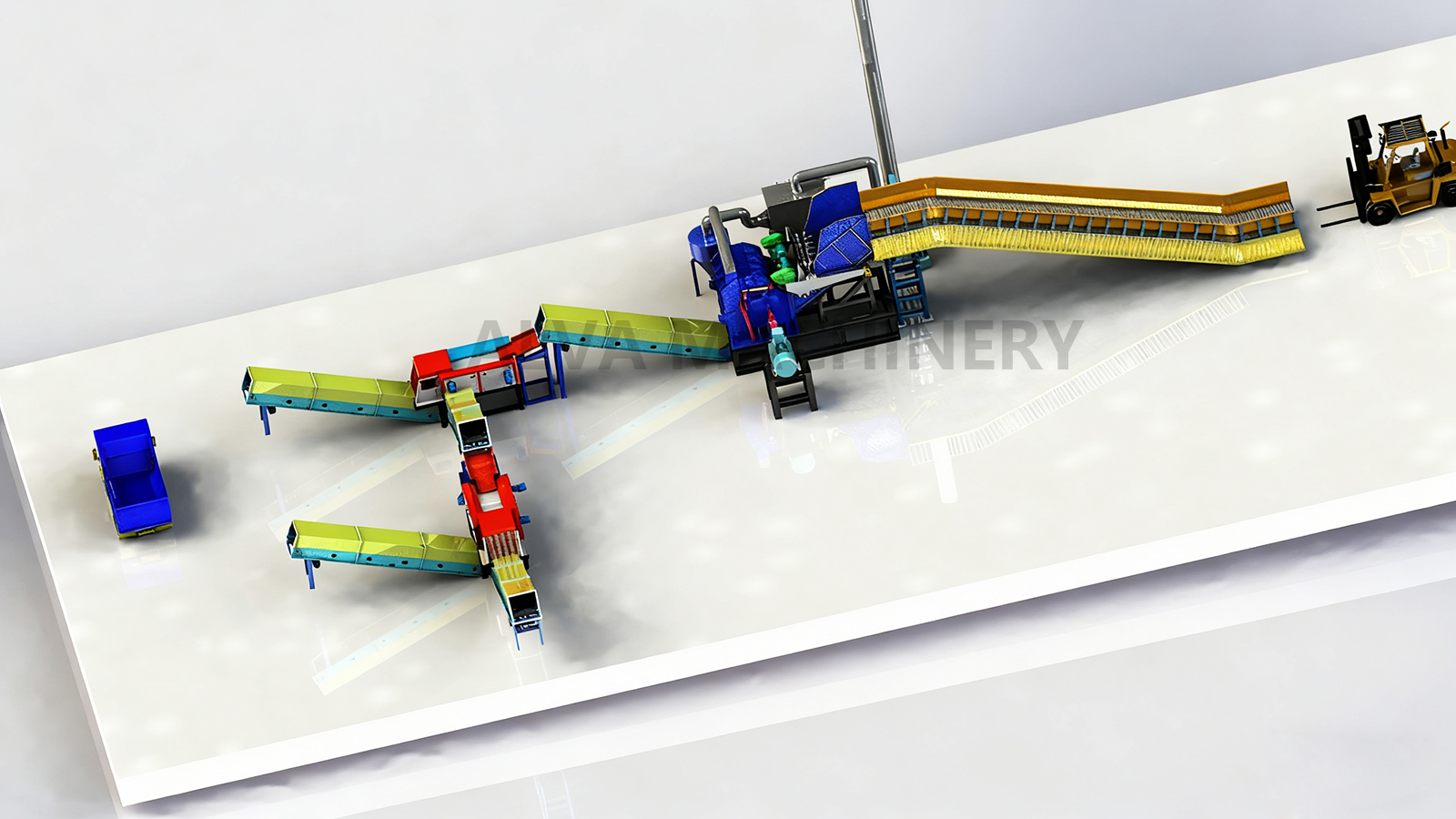

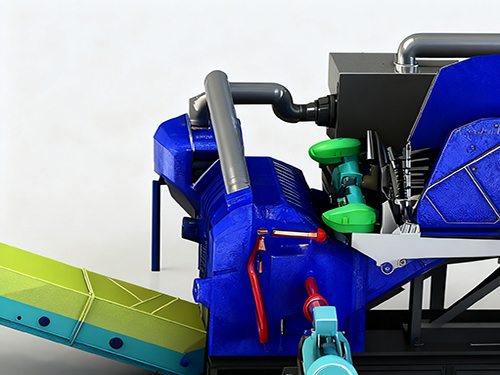

The 750 metal shredder is a medium-sized machine designed by Alva for high-capacity production. It serves steel groups and large-scale recycling companies, specializing in the large-scale crushing of bulk metal materials such as scrap steel, scrap iron, and end-of-life equipment. Equipped with a 185-220kW motor and a feed port measuring 900×1000mm, it boasts a crushing capacity of 15-20 tons per hour. Its hammers utilize a tungsten carbide alloy inlay process, extending their service life by 2-3 times compared to conventional hammers. It efficiently crushes heavy scrap materials under 25mm thick. Its innovative "integrated crushing and magnetic separation" structure simultaneously separates metallic and non-metallic impurities during the crushing process, achieving a purification rate exceeding 99%. Combined with a remote intelligent control system, it enables real-time monitoring of the equipment's operating status and provides fault warnings, meeting the intelligent production needs of modern factories.

| Availability: | |

|---|---|

| Quantity: | |

01

Constructed from high-quality, high-strength steel, the overall structure has been optimized through finite element analysis, ensuring both rigidity and toughness. It can withstand the tremendous impact forces generated during scrap metal crushing and resists deformation during long-term use. The surface of the machine has been treated with corrosion and rust prevention, making it suitable for a variety of working environments, including workshops and outdoor environments, significantly improving the machine's durability and maintenance intervals.

02

Welding: The machine body and key components are welded with exquisite craftsmanship, utilizing fully automated CNC welding technology. The welds are uniform, full, and strong. Rigorous flaw detection inspections ensure that welds are free of defects such as pores and cracks. The machine can withstand the high impact and vibration of crushing operations, ensuring structural stability and reliability, and laying a solid foundation for long-term, stable operation.

03

Motor: The dedicated motor is highly efficient and energy-efficient, delivering powerful and stable power output. Utilizing advanced variable frequency speed regulation technology, the motor intelligently adjusts speed according to load changes, significantly reducing energy consumption while maintaining crushing power. The motor is equipped with an efficient heat dissipation system, maintaining a suitable temperature even during long-term continuous operation, effectively extending the motor's service life and reducing the likelihood of downtime.

04

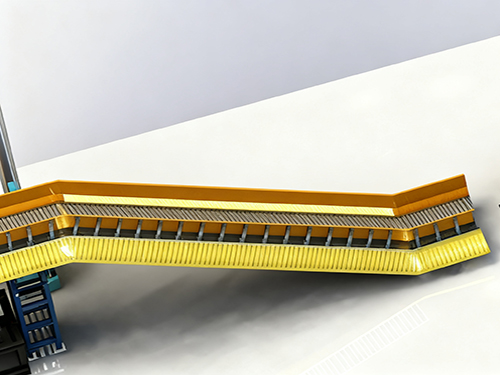

Conveying: The conveying system features a modular design, ensuring precise and smooth connection between each conveyor belt. The conveyor belts are made of a special, highly wear-resistant and tensile-resistant material, with anti-slip and anti-sticking treatments. They can stably convey scrap steel and iron of varying specifications, effectively preventing material jamming and slipping during conveying. The conveying speed can be flexibly adjusted according to production needs. Intelligent sensors monitor conveying status in real time, ensuring efficient and orderly material flow and improving overall production efficiency.

| Model | Feed Size (mm) | Production Capacity | Energy Consumption | Energy Consumption | Load Bearing | External Dimensions | External Dimensions | External Dimensions | External Dimensions |

| Monolithic Output (th) | Fan Motor Power (kW) | Distribution Transformer Requirements (kVA) | Weight (kg) | Length (L, m) | Width (W, m) | Height (H, m) | Floor Area (㎡) | ||

| ALVA-MCM-75 | 900 | 1 | 75 | 125 | 5 | 4 | 3.7 | 3 | 12 |

| ALWA-MOM-110 | 1000 | 1.5 | 110 | 160 | 11 | 4 | 4 | 3.5 | 96 |

| ALWA-MOM-132 | 1260 | 2 | 132 | 200 | 16 | 4.5 | 4.8 | 3.5 | 140 |

| ALMW-MOM-160 | 1460 | 3-4 | 160 | 250 | 26 | 5 | 4.9 | 3.5 | 160 |

| ALVA-MCM-200 | 1500 | 4-5 | 200 | 315 | 35 | 6 | 4.9 | 3.5 | 250 |

| ALVA-MCM-315 | 1600 | 6-7 | 315 | 500 | 40 | 6 | 4.9 | 3.5 | 250 |

| ALVA-MCM-450 | 1600 | 8-9 | 450 | 630 | 55 | 7 | 4.9 | 4 | 300 |

| ALVA-MCM-630 | 1800 | 10-11 | 630 | 10,000 | 75 | 7.5 | 6 | 4 | 400 |

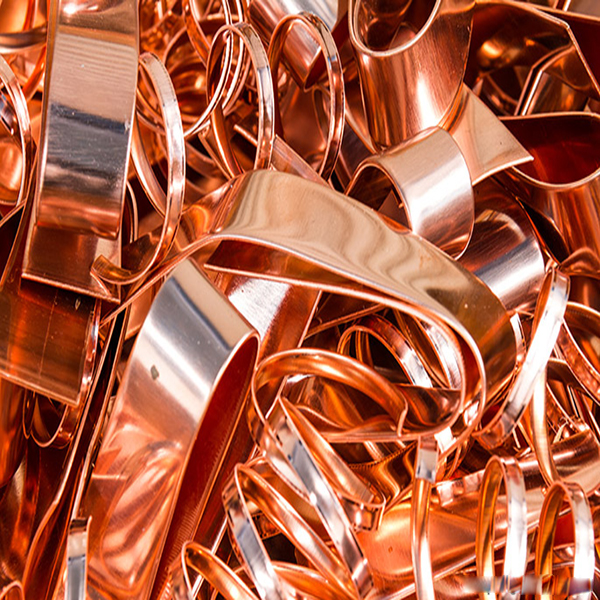

Scrap Metal

Scrap Iron

Scrap Copper

aluminum-scrap

Can-disposal

Waste bicycle

Waste paint bucket

Waste motorcycle

Waste Car

Waste plastics

Waste appliances

Customizable

|  |  |  |  |  |

|  |  |  |  |  |

We crush and recycle all kinds of raw aluminum, aluminum alloys, aluminum profiles, thermally-insulated aluminum, and waste cans.

Preparation: Check all parts of the equipment to ensure they are normal, clean the scrap aluminum to be crushed and transport it to the feed port.

Start the equipment: Turn on the crusher according to the instructions on the operation panel, and start feeding evenly after it runs smoothly without load.

Crushing operation: The scrap aluminum is crushed in the crushing chamber, and the equipment operation status is monitored during the process.

Discharge collection: The crushed aluminum material is discharged and collected and processed by screening.

Shutdown and cleaning: After the operation is completed, turn off the equipment and clean up the residual materials and equipment.

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

FAQ

Q1: Do you customize products for customers?

A1: Yes, we can customize and produce crushing machinery according to customers' requirements or drawings.

Q2: How about the quality of your products?

A2: We can provide you with samples for quality inspection. If you order, we guarantee the same quality as the sample. If there is a quality problem, we can sign an agreement and let our company perform the duties.

Q3: How can we trust your factory?

A3: We suggest that you come to our factory to see the goods, verify the real situation of the products, and learn more about our factory.

Q4: Why do prices change so often?

A4: The price depends on the latest prices of raw materials.

Q5: What about contract signing?

A5: If you are satisfied with the product and our service, you can sign a contract with us, pay a deposit, and then we will produce the machine as soon as possible. If you are far away, we can sign the contract by fax. We will ensure the quality of products and accessories complete.

Q6: What about delivery?

A6: When the product is ready, it will be delivered to you after full payment. Technical guidance will be provided.